With the improvement of living standard, plastic plays a more significant role in our life. However, the frequently exposed quality problems of plastic products make people full of doubts about the safety of the most exposed “plastic” in their daily life.

As ordinary consumers of us, how to distinguish the quality of plastic bottles, choose safe and reliable products?

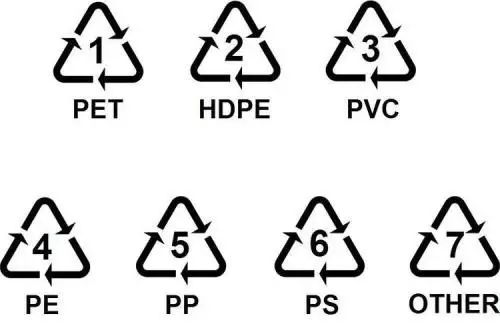

The Society of Plastics Industry (SPI) has a logo code for the type of plastic used in Plastics. It’s a three-arrow “Recycling logo” with a number and an acronym to indicate the type of plastic. The SPI logo scheme is now used in many countries around the world. China set almost identical standards in 1996.

- PETE stands for polyethylene terephthalate, a material commonly used in water bottles and carbonated drinks.

Use: heat resistant to 70℃, only suitable for warm or frozen drinks, high temperature or heating deformation, and harmful substances. Prolonged exposure may also release the carcinogenic DEHP.

Suggestion: Do not recycle beverage bottles, do not hold hot water or use them as storage containers for other items.

2. HDPE stands for high density polyethylene.

Usage: it is commonly used in cleaning products, bath products, white medicine bottles, etc. At present, plastic bags used in supermarkets and shopping malls are mostly made of this material.

Features: can withstand 110℃ high temperature, marked with food plastic bags can be used to contain food.

3. PVC: polyvinyl chloride

Application: plastic pipe, raincoat, plastic film, etc.

Features: Strong plasticity, low price. Heat resistance to 80℃, high temperature is easy to produce hydrogen chloride, into the human body, may cause breast cancer, newborn birth defects and other diseases.

Suggestion: Use sparingly in packaged foods. If in use, never allow it to get hot.

4. LDPE: low density polyethylene

Use: plastic film, etc.

Features: heat resistance is not strong, over 110℃ will appear hot melt phenomenon, easy to be dissolved by oil.

Advice: Don’t microwave crayfish wrapped in plastic wrap, and wear layers of gloves to prevent oil from seeping into your hands.

5. PP (polypropylene)

Usage: it is the only plastic box that can be put into microwave oven.

Features: can withstand temperature above 100℃.

Suggestion: some microwave lunch boxes, the box body is no. 5 PP, but the lid is made of no. 1 PE, PE can not withstand high temperature, so to be safe, the container into the microwave, should take off the lid.

6. PS (Polystyrene)

Usage: It is used to make instant noodle box and snack box.

Properties: 70-90 degrees heat resistance, hot drinks or acid and alkali will produce toxins.

Suggestion: Avoid strong acid (such as orange juice) or strong alkaline substances due to high temperature when using.

7. PC and other classes.

Usage: baby bottle. It’s controversial because it contains bisphenol A. In theory, as long as in the process of making PC, 100 percent of bisphenol A is converted into plastic structure, it means that the product is completely free of bisphenol A, let alone released.