Definition: Post Consumer Recycle(PCR) is the recycled product of waste created by consumer

1. How is PCR plastic made?

The production of PCR plastics starts with the collection of post-consumer waste. Through specialised sorting (manual or otherwise), thorough cleaning and reheating and grinding, the PCR granule is produced. This granulate is then used to make new products.

2. How PCR Plastics are Used

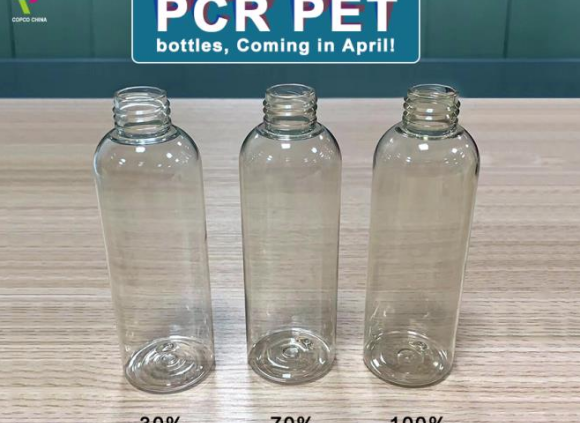

PCR plastics can be used to make similar materials, such as PET bottles for beverages. While some repurposed plastics can become too brittle and weak for use, they can be mixed with virgin materials to strengthen them. This doesn’t eliminate the need for new materials but helps reduce the amount of new plastic needed. In some cases, however, you are able to turn used plastics into pellets, which can then be used to make durable, FDA-approved materials again. Should your recycled plastics become too weak to use for stronger types of packaging, you can recycle it into other forms of packaging for use, such as plastic bags or coverings.

3. What is the advantage of PCR plastic over virgin plastic?

Reuse of plastic that has already been made is not only a cost-effective process, but also a waste reduction process. In addition, processing the used plastic requires less water, less fossil fuels and less energy. The use of PCR also has indirect benefits. All the benefits are listed below:

Less use of fossil resources

Reduction of CO2 emissions up to 85%

Less water consumption

Less energy consumption

Reduction of the amount of waste

Can be recycled after use

4. What Are the Drawbacks to PCR Resin?

The most common complaints around PCR resins are occasional black flecks, grey/yellow tinting, and gels in the material. Even so, when used in the correct application such as ag films or trash bags, these minor defects do not affect the overall function of the product and are strictly cosmetic. While PCR resins may be subject to slight variations in color, this can be overcome by choosing a reliable provider.

5. Positive Environmental Benefits?

Virgin resins such were originally processed from fossil fuels and turned into plastics. When these PCR resins are reused and transformed into new products, new fossil fuels are not required, which has exponential environmental implications.

According to data from the Environmental Protection Agency, recycled plastics account for far less environmental impact than their virgin counterparts. As a matter of fact, many studies suggest recycled plastics contain over 25% less green house/carbon gas emissions than virgin resins. The more PCR resins you include in your products, the higher impact you can make on saving the environment.

6. How Does the Price of PCR Resin Compare to Virgin Resin?

In the past, the cost of post consumer resin has been a bit higher than new virgin resins. This can be attributed to the extensive cleaning, sorting, and processing required to recapture the recycled resins.

As the overall cost of petroleum-based raw materials continually increases — however — the cost of PCR resins are projected to stay the same. In addition, when more consumers recycle plastics, the law of supply and demand will keep PCR resins extremely attractive in comparison to virgin resins.